Process Analysis

Novatec is able to carry out analysis of manufacturing processes to implement technological solutions aimed at the improvement and efficiency of business performance.

The analysis will be presented using the ‘as is” (mapping the current process) and ‘to be” (desired future situation) schemas.

Based on the need expressed by the customer, the process is broken down into all its elementary stages. Faced with this detailed analysis, a feasibility study is constructed that indicates the possible interventions to be carried out and the most appropriate technology to be used.

Afterward, the company makes a decision on whether to implement the identified solution independently or continue to trust Novatec for the machine or turnkey system design, construction, and supply.

|

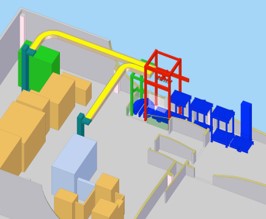

Robotic Materials Handling and Machine Tending System 4.0 (button 0) Problem: gain efficiency, reduce the danger by removing the operators involved in the loading/unloading of the line through the introduction of an automatic system of handling and depalletization/ palletizing Activity carried out by Novatec: 1) analysis of customer needs and operator activities, 2) functional design of the compact system for depalletising/loading empty bottles and unloading/re-lifting filled bottles, 3) design, construction and turnkey supply of the line (in collaboration with the University of L’Aquila and Gexma srl) |

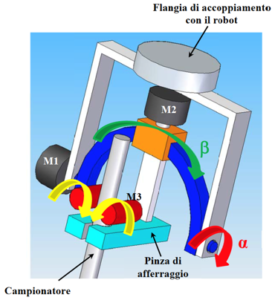

Dust sampling system in Bin Technological consulting according to the following scheme: 1) Technical specification of the dust sampling system 2) Analysis of commercial systems 3) Concept of a new system 4) Definition of the lay-out and dimensioning of the robotic system to reach 10 sampling points |  |